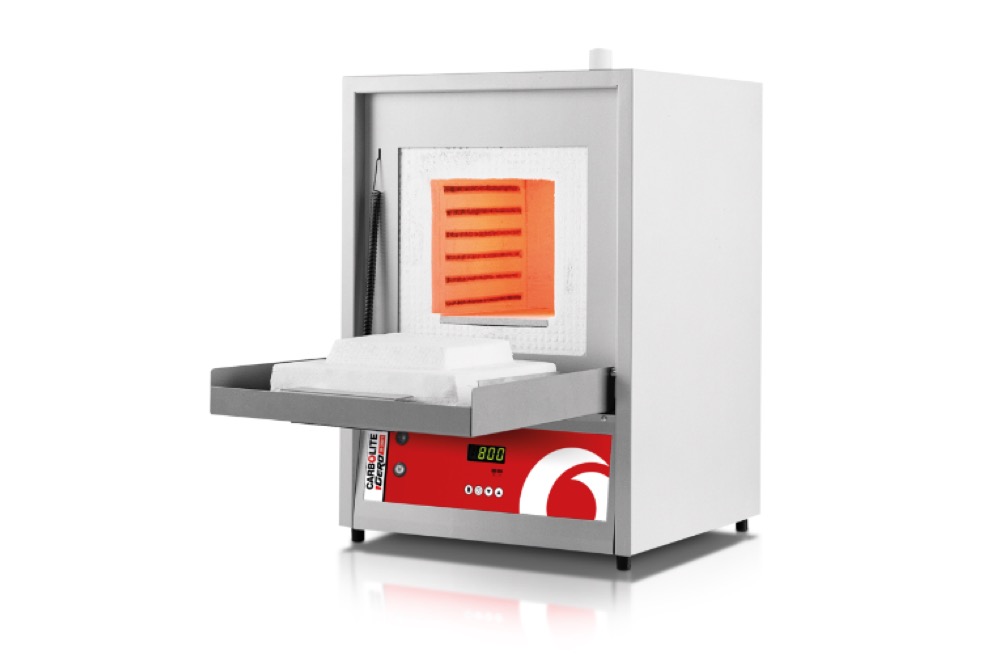

Carbolite Gero – Laboratory Chamber Furnace

Carbolite Gero’s extensive chamber furnace range has a maximum operating temperature of 1800°C and chamber capacities up to 725 liters. They are suitable for a variety of laboratory, pilot scale and industrial applications. Although there is flexibility in size and temperature, if the application requires the use of modified atmosphere (above 1100°C) or vacuum then a furnace from Carbolite Gero’s tube furnace range should be selected.

An extensive range of chamber / muffle furnaces is available for your laboratory.

Whether you need a small bench mounted affordable solution or a high temperature furnace built to the highest quality, Carbolite Gero has a model that is sure to meet your needs and budget. Ranging from the entry level ELF models at 1100°C through to the laboratory sized HTF model with a maximum temperature of 1800°C our experience of building quality furnaces for customers around the globe over the last eight decades has ensured that the Carbolite Gero name is synonymous with Leading Heat Technology.

Whether you need a front, top or bottom loading chamber furnace our extensive portfolio virtually guarantees there is an appropriate standard solution that will meet your requirements but of course our bespoke design service allows us to meet almost every scenario we have ever been consulted about.

Key Features

- High-Temperature Capability: The furnace can reach temperatures up to 1800°C, accommodating a wide range of laboratory heat treatment processes.

- Advanced Temperature Control: Equipped with sophisticated temperature controllers, it ensures accurate and consistent thermal management for precise experimental conditions.

- Robust Construction: Built with durable materials, the furnace offers longevity and reliability, making it suitable for demanding laboratory environments.

Available Models

Technical Specifications

ELF

CWF, CWF-B and CWF-BAL

- AA Nebulizers: AA Nebulizers for Flame Atomization System

- Burner Chamber Assemblies for PerkinElmer: Agilent burner chamber assemblies for PerkinElmer AA systems are designed to provide the best precision, efficient drainage, minimal burner blockage, and reduced interferences.

- Burner System Components for PerkinElmer: Agilent burner components for PerkinElmer AA systems are designed to provide the best precision, efficient drainage, minimal burner blockage, and reduced interferences.

- Burners: The Mark 7 burner fits all current Agilent AA instruments and the earlier SpectrAA series instruments and is compatible with the Mark V, VI, and 7 spray chambers.

- Burners for PerkinElmer: Agilent burner chamber assemblies for PerkinElmer AA systems are designed to provide the best precision, efficient drainage, minimal burner blockage, and reduced interferences.

- Mark 7 Spray Chamber Supplies: Mark 7 Spray Chambers for Flame Atomization System.

- Mark VI Spray Chamber Supplies: The Mark VI spray chamber was used with older model AA instruments. It has many of the design features and benefits of the Mark 7 design.

- Nebulizers and Supplies for PerkinElmer: Agilent nebulizers for PerkinElmer AA systems provide the best precision, efficient drainage, minimal burner blockage, and reduced interferences.

RWF

- Accessories for SPS 3: Agilent offers a range of optional accessories for the SPS 3, which are designed to improve the quality of analytical results and reduce running costs.

- SPS 3 Diluter Spares and Maintenance: These spares and maintenance kits support the optional diluter for the SPS 3, which powers your sample preparation and frees your laboratory staff for other tasks.

- SPS 3 Probes: Agilent offers a range of inert probe options for the SPS 3, including an optional carbon fiber–reinforced fluoropolymer probe.

- SPS 3 Racks: The SPS 3 is compatible with a wide range of low-cost, commercially available sample racks, providing flexibility in sample handling and accommodating tubes from 90 x 13 mm to 21 x 30 mm.

- SPS 3 Start-up and Operating Supplies Kit: Agilent’s spares kit provides the typical operating supplies required for moderate use of the SPS 3.

- SPS 3 Test Tubes: Agilent offers a range of test tubes and larger capacity digestion vessels that are compatible with the sample racks supported with the SPS 3, providing flexibility in sample handling and allowing tubes from 16 to 30 mm od to be used.

- SPS 3 Tubing: The SPS 3 features an integrated peristaltic pump, providing an on-demand flow through rinse. This conserves rinse solution and minimizes sample contamination and carryover.

| CGH Model | Max. temp. [°C] | Heat-up time [mins] | Max. continuous operating temp. [°C] | Dimensions: Usable chamber H x W x D [mm] | Dimensions: External H x W x D [mm] | Temperature uniformity of ±5°C within H x W x D [mm] | Volume [litres] | Max. power [W] | Holding power [W] | Thermocouple type | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ELF 11/6 | 1100 | 28 | 1000 | 165 x 180 x 210 | 580 x 410 x 420 | 125 x 140 x 140 | 6 | 2000 | 900 | K | 24 |

| ELF 11/14 | 1100 | 43 | 1000 | 210 x 220 x 310 | 630 x 450 x 520 | 170 x 180 x 205 | 14 | 2600 | 1300 | K | 31 |

| ELF 11/23 | 1100 | 26 | 1000 | 235 x 255 x 400 | 715 x 505 x 690 | 195 x 215 x 305 | 23 | 5000 | 1550 | K | 52 |

| CGH Model | Max. temp. [°C] | Heat-up time [mins] | Max. continuous operating temp. [°C] | Dimensions: Usable chamber H x W x D [mm] | Dimensions: External H x W x D [mm] | Dimensions: External with door open H x W x D [mm] | Temperature uniformity of ±5°C within H x W x D [mm] | Volume [litres] | Max. power [W] | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|

| Standard Chamber Furnaces | ||||||||||

| CWF 11/5 | 1100 | 47 | 1000 | 135 x 140 x 250 | 585 x 375 x 485 | 800 x 375 x 485 | 85 x 90 x 110 | 5 | 2400 | 30 |

| CWF 11/13 | 1100 | 90 | 1000 | 200 x 200 x 325 | 655 x 435 x 610 | 905 x 435 x 610 | 120 x 120 x 185 | 13 | 3100 | 47 |

| CWF 11/23 | 1100 | 36 | 1000 | 235 x 245 x 400 | 705 x 505 x 675 | 990 x 505 x 675 | 155 x 165 x 285 | 23 | 7000 | 68 |

| CWF 12/5 | 1200 | 51 | 1100 | 135 x 140 x 250 | 585 x 375 x 485 | 800 x 375 x 485 | 85 x 90 x 125 | 5 | 2400 | 30 |

| CWF 12/13 | 1200 | 80 | 1100 | 200 x 200 x 325 | 655 x 435 x 610 | 905 x 435 x 610 | 120 x 120 x 200 | 13 | 3100 | 47 |

| CWF 12/23 | 1200 | 45 | 1100 | 235 x 245 x 400 | 705 x 505 x 675 | 990 x 505 x 675 | 155 x 165 x 325 | 23 | 7000 | 68 |

| CWF 12/65 | 1200 | 40 | 1100 | 278 x 388 x 595 | 885 x 780 x 945 | 1245 x 780 x 945 | 178 x 288 x 455 | 65 | 14000 | 165 |

| CWF 13/5 | 1300 | 75 | 1200 | 135 x 140 x 250 | 585 x 375 x 485 | 800 x 375 x 485 | 85 x 90 x 150 | 5 | 2400 | 30 |

| CWF 13/13 | 1300 | 115 | 1200 | 200 x 200 x 325 | 655 x 435 x 610 | 905 x 435 x 610 | 120 x 120 x 225 | 13 | 3100 | 47 |

| CWF 13/23 | 1300 | 55 | 1200 | 235 x 245 x 400 | 705 x 505 x 675 | 990 x 505 x 675 | 155 x 165 x 340 | 23 | 7000 | 68 |

| CWF 13/36 | 1300 | 47 | 1200 | 250 x 320 x 450 | 810 x 690 x 780 | 1105 x 690 x 780 | 1105 x 690 x 780 | 36 | 9000 | 100 |

| CWF 13/65 | 1300 | 45 | 1200 | 278 x 388 x 595 | 885 x 780 x 945 | 1245 x 780 x 945 | 178 x 288 x 520 | 65 | 14000 | 165 |

| Burn-off Chamber Furnaces | ||||||||||

| CWF-B 11/13 | 1100 | 103 | 1000 | 200 x 200 x 325 | 655 x 435 x 610 | 905 x 435 x 610 | n/a | 13 | 3100 | 47 |

| CWF-B 12/13 | 1200 | 130 | 1100 | 200 x 200 x 325 | 655 x 435 x 610 | 905 x 435 x 610 | n/a | 13 | 3100 | 47 |

| Chamber Furnace with Integral Balance | ||||||||||

| CWF-BAL 11/21 | 1100 | 60 | 1000 | 215 x 245 x 400 | 705 x 505 x 675 (400 x 170 x 500) | 990 x 505 x 675 | n/a | 21 | 7000 | 80 |

| CGH Model | Max. temp. [°C] | Heat-up time [mins] | Max. continuous operating temp. [°C] | Dimensions: Usable chamber H x W x D [mm] | Dimensions: External H x W x D [mm] | Temperature uniformity of ±5°C within H x W x D [mm] | Volume [litres] | Max. power [W] | Holding power [W] | Thermocouple type | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RWF 11/5 | 1100 | 10 | 1000 | 130 x 160 x 250 | 585 x 375 x 325 | 800 x 375 x 325 | 5 | 2750 | 680 | K | 28 |

| RWF 11/13 | 1100 | 11 | 1000 | 195 x 210 x 325 | 655 x 435 x 610 | 905 x 435 x 610 | 13 | 5000 | 1200 | K | 45 |

| RWF 11/23 | 1100 | 13 | 1000 | 220 x 260 x 400 | 705 x 505 x 675 | 990 x 505 x 675 | 23 | 9100 | 1800 | K | 65 |

| RWF 12/5 | 1200 | 12 | 1100 | 130 x 160 x 250 | 585 x 375 x 485 | 800 x 375 x 485 | 5 | 2750 | 820 | R | 28 |

| RWF 12/13 | 1200 | 13 | 1100 | 195 x 210 x 325 | 655 x 435 x 610 | 655 x 435 x 610 | 13 | 5000 | 1450 | R | 45 |

| RWF 12/23 | 1200 | 15 | 1100 | 220 x 260 x 400 | 705 x 505 x 675 | 990 x 505 x 675 | 23 | 9100 | 2100 | R | 65 |

| CGH Model | Max. temp. [°C] | Heat-up time [mins] | Max. continuous operating temp. [°C] | Dimensions: Usable chamber H x W x D [mm] | Dimensions: External H x W x D [mm] | Temperature uniformity of ±5°C within H x W x D [mm] | Volume [litres] | Max. power [W] | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|

| VCF 12/5 | 1200 | 102 | 260 x 155 x 130 | 660 x 530 x 405 (Floor-standing) | 5 | 2500 | 900 | R | 50 |

| VCF 12/10 | 1200 | 138 | 365 x 180 x 155 | 765 x 555 x 430 (Floor-standing) | 10 | 3000 | 1200 | R | 60 |

| VCF 12/23 | 1200 | 125 | 450 x 250 x 200 | 850 x 600 x 500 (Floor-standing) | 23 | 6000 | 2500 | R | 130 |

| VCF 12/100 | 1200 | 150 | 600 x 410 x 410 | 1100 x 930 x 950 (Floor-standing) | 100 | 15000 | 6000 | R | 200 |

| CGH Model | Max. temp. [°C] | Heat-up time [mins] | Dimensions: Usable chamber H x W x D [mm] | Dimensions: External with door open H x W x D [mm] | Volume [litres] | Holding power [W] | Max. power [W] | Thermocouple type | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|

| RHF 14/3 | 1400 | 33 | 120 x 120 x 205 | 655 x 435 x 610 (905) (Bench-top) | 3 | 1900 | 4500 | R | 42 |

| RHF 14/8 | 1400 | 22 | 170 x 170 x 270 | 705 x 505 x 675 (990) (Bench-top) | 8 | 3200 | 8000 | R | 64 |

| RHF 14/15 | 1400 | 35 | 220 x 220 x 310 | 810 x 690 x780 (1105) (Bench-top) | 15 | 2900 | 10000 | R | 125 |

| RHF 14/35 | 1400 | 38 | 250 x 300 x 465 | 885 x 780 x 945 (1245) (Benchtop) | 35 | 6000 | 16000 | R | 179 |

| RHF 15/3 | 1500 | 45 | 120 x 120 x 205 | 655 x 435 x 610 (905) (Bench-top) | 3 | 2000 | 4500 | R | 46 |

| RHF 15/8 | 1500 | 40 | 170 x 170 x 270 | 705 x 505 x 675 (990) (Bench-top) | 8 | 3500 | 8000 | R | 61 |

| RHF 15/15 | 1500 | 46 | 220 x 220 x 310 | 810 x 690 x 780 (1105) (Bench-top) | 15 | 3000 | 10000 | R | 125 |

| RHF 15/35 | 1500 | 46 | 250 x 300 x 465 | 885 x 780 x 945 (1245) (Bench-top) | 35 | 6200 | 16000 | R | 178 |

| RHF 16/3 | 1600 | 42 | 120 x 120 x 205 | 655 x 435 x 610 (905) (Bench-top) | 3 | 2300 | 4500 | R | 42 |

| RHF 16/8 | 1600 | 35 | 170 x 170 x 270 | 705 x 505 x 675 (990) (Bench-top) | 8 | 4000 | 8000 | R | 61 |

| RHF 16/15 | 1600 | 58 | 220 x 220 x 310 | 810 x 690 x 780 (1105) (Bench-top) | 15 | 3500 | 10000 | R | 140 |

| RHF 16/35 | 1600 | 113 | 250 x 300 x 465 | 1530 x 900 x 1020 (1885) (Floor-standing) | 35 | 7000 | 16000 | R | 270 |

| CGH Model | Max. temp. [°C] | Heat-up time [mins] | Dimensions: Usable chamber H x W x D [mm] | Dimensions: External with door open H x W x D [mm] | Volume [litres] | Max. power [W] | Thermocouple type | Weight [kg] |

|---|---|---|---|---|---|---|---|---|

| HTF 17/5 | 1700 | 50 | 158 x 150 x 225 | 565 x 830 x 650 (850) (Bench-top) | 5 | 4050 | B | 109 |

| HTF 17/10 | 1700 | 44 | 232 x 200 x 225 | 565 x 830 x 650 (850) (Bench-top) | 10 | 5920 | B | 133 |

| HTF 18/4 | 1800 | 65 | 140 x 140 x 190 | 565 x 830 x 650 (850) (Bench-top) | 4 | 4650 | Pt20%Rh / Pt40%Rh | 115 |

| HTF 18/8 | 1800 | 56 | 210 x 190 x 190 | 565 x 830 x 650 (850) (Bench-top) | 8 | 6200 | Pt20%Rh / Pt40%Rh | 128 |

Carbolite Gero – Leading Heat Technology – Ovens and Furnaces Up to 3,000 °C

More Products

The Carbolite Gero brand is synonymous with high quality, leading heat technology in the design and manufacture of laboratory and…