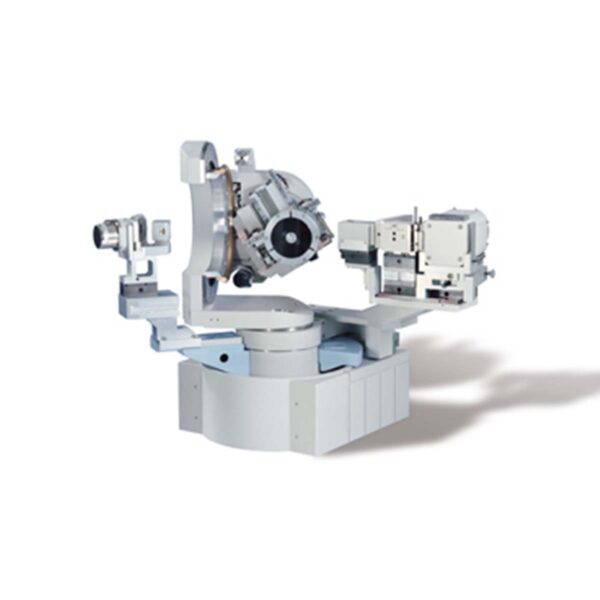

FOSS – Dairy Powder Analyzer – NIRS™ DS2500

The NIRS™ DS2500 Dairy Powder Analyser helps you to improve yield in your dairy powder production. Designed for use in the laboratory or at the production line, the NIRS™ DS2500 is a practical quality control tool ideal for routine production control and monitoring of final product quality.

Value

Routine production control. Monitoring of final product quality. More yield with reduced energy.

Sample type

Dairy powders and ice-cream mix.

Parameters

Fat, protein, moisture, ash, lactose, acidity and more.

Technical Specification

| Dimensions (WxDxH) | 375 x 490 300 mm | |

| Weight | 27 kg | |

|---|---|---|

| Degree of protection | IP 65 | |

| Measurement mode | Reflectance or transflectance (for liquids) | |

| Wavelength range | 400 – 2500 | |

| Detector | Silicon (400 – 1100 nm), lead sulfide (1100 – 2500 nm) | |

| Optical bandwidth | 8.75 +-0.1 nm | |

| Spectral resolution | 0.5 nm | |

| Number of data points | 4200 | |

| Absorbance range | Up to 2 AU | |

| Analysis time | <1 minute* | |

| Wavelength accuracy | <0.05 nm | |

| Wavelength precision (based on a single analyser) | Wavelength precision (based on a single analyser) | |

| <0.005 nm | <0.005 nm | |

| Wavelength precision instrument-to-instrument (based on a group of analysers) | <0.02 nm | |

| Photometric noise** | ||

| 400 – 700 nm < 50 micro au | 400 – 700 nm < 50 micro au | |

| 700 – 2500 nm < 20 micro au | 700 – 2500 nm < 20 micro au | |

| *Adjustable **Noise = RMS for 10 co-added, 10 second scans | ||

Key Features

NIRS™ DS2500 Dairy Powder Analyser

- FossConnect™: FossConnect™ is a centralised networking management solution for the NIRS™ DS2500 that helps you reduce your production costs and secure the quality of your products. With FossConnect™, you can manage, configure and monitor your instruments remotely from any internet-enabled computer and safeguard your data for whenever you need it.

- FossAssure™: FossAssure™ is a NIRS™ DS2500 digital service designed to reduce product waste, secure brand protection and increase profitability by ensuring the quality and precision of your analytical results. Besides, FossAssure™ services will also improve instrument uptime and reduce production costs by optimising the operation and the performance of your instruments.

- NIR technology: NIR (Near Infrared) reflectance method yields accurate representative analyses for solid or semi-solid dairy products. Plus, analysis can be easily replicated. Versatility and stability across the full spectral range from 400 to 2500 nm.

The Next Step in Dairy Powder Analysis With NIR

Key Industries

- Biopharmaceutical and Biotechnology

- Education & Academics

- Environmental

- Food & Beverage

- Pharmaceutical

More Products

FOSS creates end-to-end solutions that secure and improve food quality. From raw material to finished product. Our analysis instruments refine…