Foss – Dumatec™ 8000

Automated Dumas analysis for quality control in food and feed laboratories. Full control of your data with remote surveillance option.

Official reference method

- AOAC 997.09 Beer, wort, brewing grains

- AOAC 990.03 Animal feed

- AOAC 992.23 Cereal grain and oilseed

- AOAC 992.15 Meat and meat products

- ISO 14891 Milk and milk products

- ISO 16634 Determination of total nitrogen

Technical Specifications

| Weight net | 65 kg |

| W × D × H (mm) | 800 x 450 x 590 (710 with autosampler) |

| Digital balance | Precision 0.1 mg (calibration starts 5 mg abs Nitrogen) 0.01 mg or better (calibration starts 1 mg abs Nitrogen) |

| Temperature range | Combustion furnace 400 – 1100°C Reduction furnace 400 – 1100°C Desorption furnace 50 – 350 °C |

| Power supply | 220 – 240 VAC, 50/60 Hz |

| Storage temperature | 5 – 40 °C |

| Performance data at 230 V | |

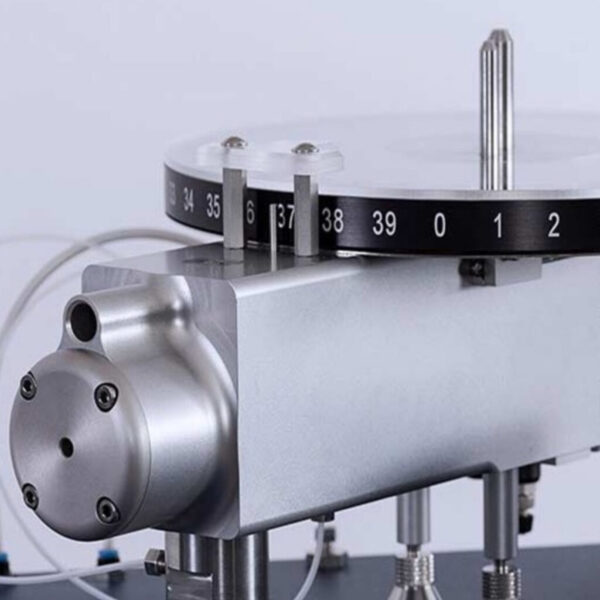

| Autosampler capacity | 3 discs with 39 positions in each; a total of 117 positions |

| Analysis time | 2 – 5 min, depending on the sample substance and weight |

| Sample weight | 0.5 mg – 300 mg (typically 100 mg). Samples with low organic matter up to 1000mg |

| Relative standard deviation | < 0.5 % with 150 mg test substance (EDTA) |

| Recovery | >99.5% |

| Detection limit | 0.003 mg N |

| Accessories and consumables: tin foils, quarts tube crucibles, sample preparation plate with plunger, capsule forming and closing device, sample holder, wool pads Reagents: copper 450g, EDTA, absorbent for liquid samples, pre-packed combustion tube | |

Key Features

Dumatec™ 8000

Reliable Dumas with reduced work

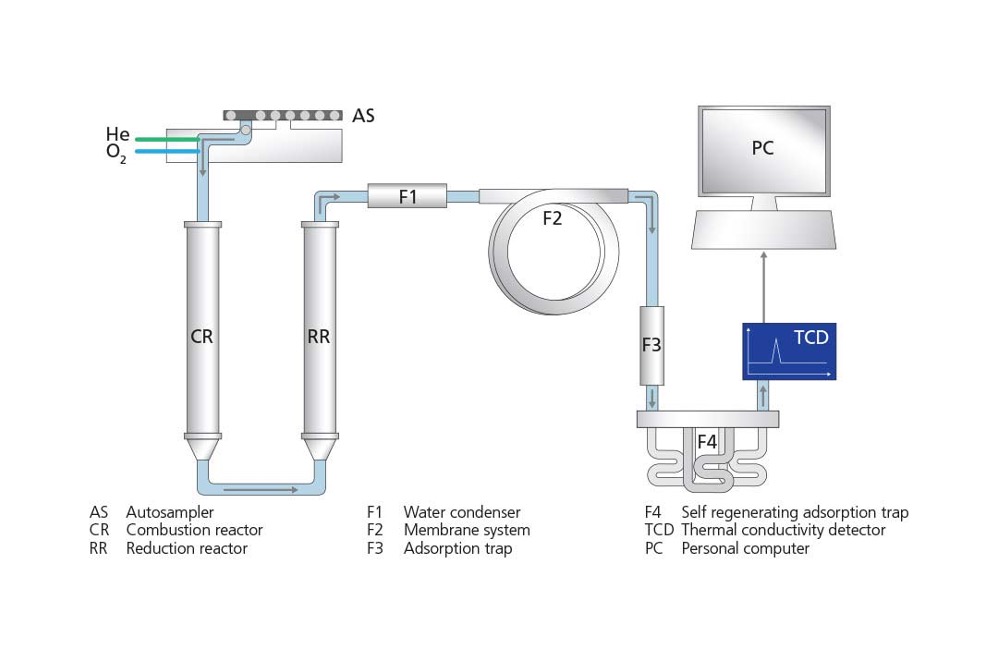

Free your laboratory resources. With Dumatec™ 8000 removal of CO2 is done automatically with the patented self-regenerating adsorption trap within a six position carousel.

Easy to use auto sampler

A smart auto sampler disc system gives you batch handling flexibility. Up to three discs can be loaded simultaneously allowing up to 117 samples to be analysed unattended.

Three-stage water filtering system

The unique three-stage water removal system increases the lifetime of the water trappacking many times. The by-product water (H2O) is separated from the gas mixture by three water traps – F1, F2 and F3. F1 is a water condensation tube. F2 is a Perma Pure gas membrane. F3 is a silica gel water trap.

Highlights

Easy to use auto sampler

A smart auto sampler disc system gives you batch handling flexibility. Up to three discs can be loaded simultaneously allowing up to 117 samples to be analysed unattended.

Reliable Dumas with reduced work

Free your laboratory resources. With Dumatec™ 8000 removal of CO2 is done automatically with the patented self-regenerating adsorption trap within a six position carousel.

Three-stage water filtering system

The unique three-stage water removal system increases the lifetime of the water trap-packing many times. The by-product water (H2O) is separated from the gas mixture by three water traps – F1, F2 and F3. F1 is a water condensation tube. F2 is a Perma Pure gas membrane. F3 is a silica gel water trap.

Protein Analysis in 3 Minutes with The New Dumatec™ 8000

Everything You Need to Know About Foss Dumatec™

More Products

FOSS creates end-to-end solutions that secure and improve food quality. From raw material to finished product. Our analysis instruments refine…