Foss – Hydrotec™ 8000

Fully automated acid hydrolysis system. Patented HydroCap™ – single use filter system. Reduced foot print and batch handling of 12 samples.

The HydrotecTM 8000 total fat solution, consisting of an extraction unit, a hydrolysis unit and a FOSS Hydrocap single filter system, allows you to perform total fat analysis in one integrated procedure.

Key Features

- Unique patented filter system: The unique, patented HydrocapTM filter avoids sample transfer and reduces the risk of human error. Laboratory costs are dramatically reduced and higher sample throughput improves cost effectiveness.

- Improving throughput at a lower cost: Simplified operation reduces the potential for human error in total fat analysis while reducing costs and improving overall sample throughput.

- Reducing risk in total fat analysis: Chemicals are added and removed by pump, improving safety and reducing the risk of error. For total fat analysis, Hydrotec 8000 can be used together with a Soxtec 8000 or ST255 Soxtec extraction unit and FOSS HydroCap single filter that works across both units.

Technical Specifications

| W x D x H (mm) | 430 x 340 x 310 (Height with lid open is 600) |

|---|---|

| Weight | 18 kg |

| Power rating | 1860 W (230 VAC version) 1660 W (120 VAC version) |

| Internal fuses (CU) | F10A250V (230 VAC version) F15A125V (120 VAC version) |

| Sample size | 0.5-2 g |

| Measurement range | 0.1-100% fat in combination with extraction |

| Repeatability | Typically ±1% relative standard deviation for 10-100% fat content in combination with extraction |

| Capacity per batch | 12 samples simultaneously |

| Hydrolysis time | Typically 2 hours, or as stated in Application |

| Modes | 2 modes; Automatic/Manual |

| Programs | 1-9 |

| Voltage | 100-120 VAC 50/60Hz or 220-240 VAC 50/60Hz depending on ordered version |

| Water supply | Two water taps – for cooling and also for rinsing water. Alternatively one tap equipped with a T-connector. Deionized or distilled water is not needed. |

| Cooling and rinsing water | Water tap: 1 litre/min, <25 °C (pressure 50 to 500 kPa or 0.5 to 5 bar). Circulating Water Cooler: 1 litre/min, <25 °C (max backpressure 20 kPa or 0.2 bar) |

| Drain | One drain/sink for rinse, acid and cooling water |

| Ventilation | Fume hood |

| Use | Indoor |

| Altitude | Up to 2000 m |

| Temperature | 5-40 °C |

| Relative humidity | Maximum 80% |

| Pollution degree | 2 |

| Protection class | IP41 |

Highlights

Acid Hydrolysis

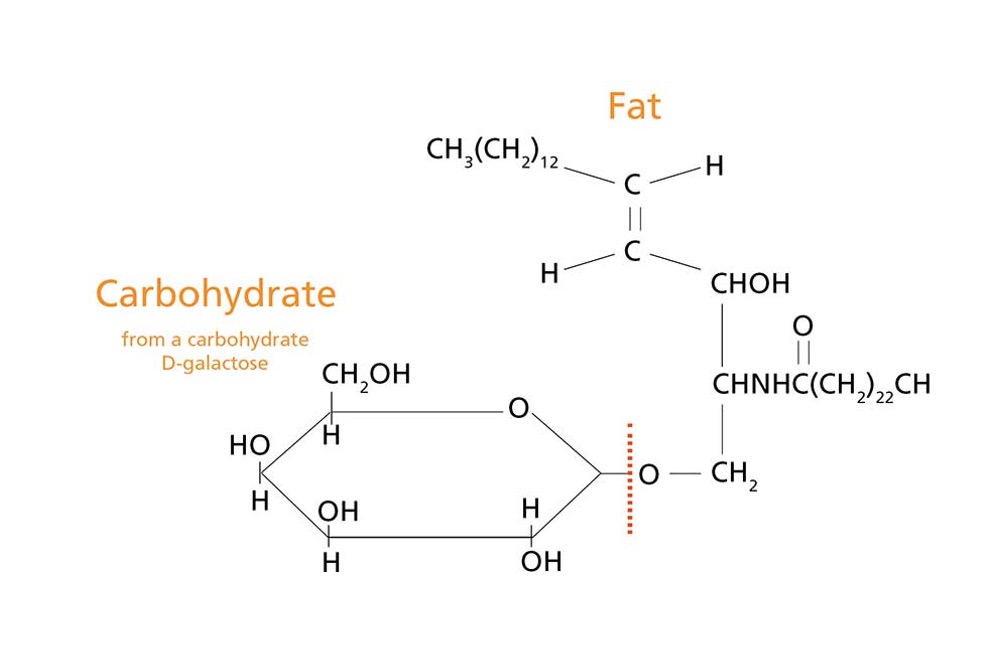

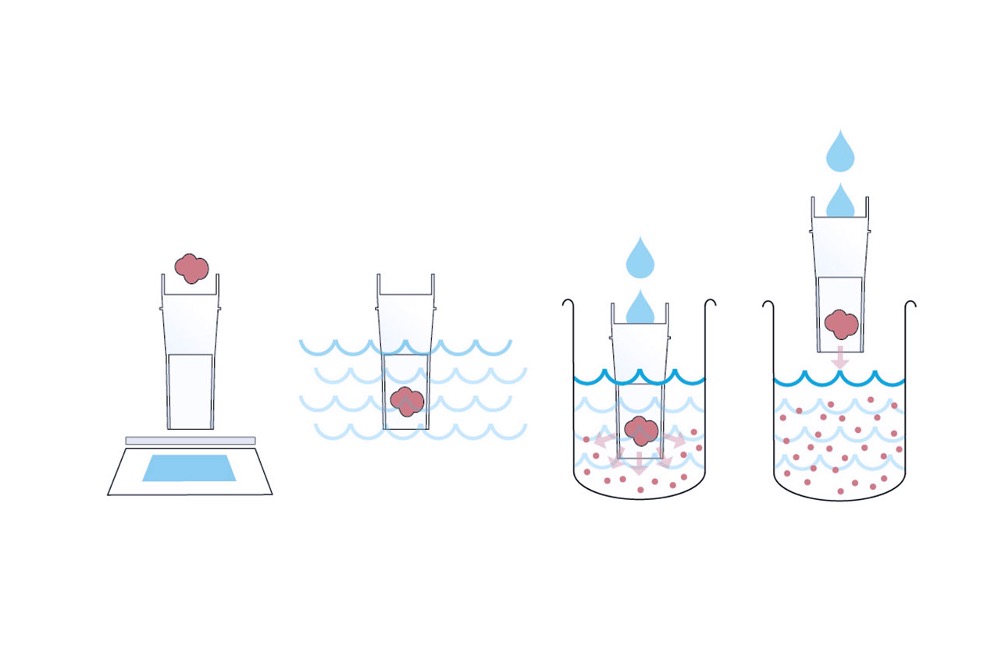

In some cases, the fat is chemically or mechanically bound to e.g. carbohydrates, salts or proteins. Acid hydrolysis breaks these bonds – making it possible to extract the fat.

Innovative System

- Chemicals are added and removed by pump, improving safety and reducing the risk of human error

- Water rinse is performed automatically

- The system is closed and releases no fumes

Simplified Process

This unique patented Hydrocap™ filter contains the sample from the initial weighing, through hydrolysis to final extraction; avoiding sample transfer errors. It is a fully automated system that performs automated acid hydrolysis and Randall improved Soxhlet extraction in one integrated process.

Batch Handling Tools

Batch handling, with no sample transfer, is used throughout the procedure. Boiling, rinsing and filtration are performed under reproducible and controlled conditions. The system offers substantial savings in terms of operator time, as well as improved analytical precision compared to manual methods.

How to Do Total Fat Analysis with The Soxtec 8000 System

More Products

FOSS creates end-to-end solutions that secure and improve food quality. From raw material to finished product. Our analysis instruments refine…